Industrial Fasteners 101: Know Your Nuts, Bolts, and Everything In Between

When you think about what holds the world together, you might picture glue or welding — but really, it’s fasteners. From the bolts in a bridge to the screws in your furniture, fasteners keep everything connected and running smoothly. According to Mordor Intelligence, the North America industrial fasteners market was valued at $20.68 billion in 2024 and is expected to reach $25.08 billion by 2030 — showing just how essential these tiny components are to nearly every industry. Let’s break down what they are, why they matter, and how to choose the right ones for the job.

Definition and Purpose

Industrial fasteners are the unsung heroes of the mechanical world. They are hardware devices specifically designed to hold two or more parts together, either permanently or temporarily. You’ll find them in furniture, airplanes, skyscrapers, and even electronics. Without them, assembling, repairing, or maintaining any structure would be far more complicated — or even impossible. Fasteners make construction efficient because they allow for easy disassembly when parts need replacing or servicing.

Their purpose goes beyond just “holding things together.” They also distribute loads, keep components aligned, and provide safety by preventing parts from coming loose under stress. In industries like automotive, aerospace, and manufacturing, the performance of a fastener can directly impact the reliability and safety of an entire system. The right selection can also save time and money by reducing maintenance needs and extending the lifespan of equipment. Even small differences in material, coating, or thread type can affect strength and corrosion resistance. The right fastener choice can mean the difference between a long-lasting product and one that fails prematurely. Once you understand this, you’ll see why fasteners are one of the most important considerations in any build.

Common Types of Industrial Fasteners

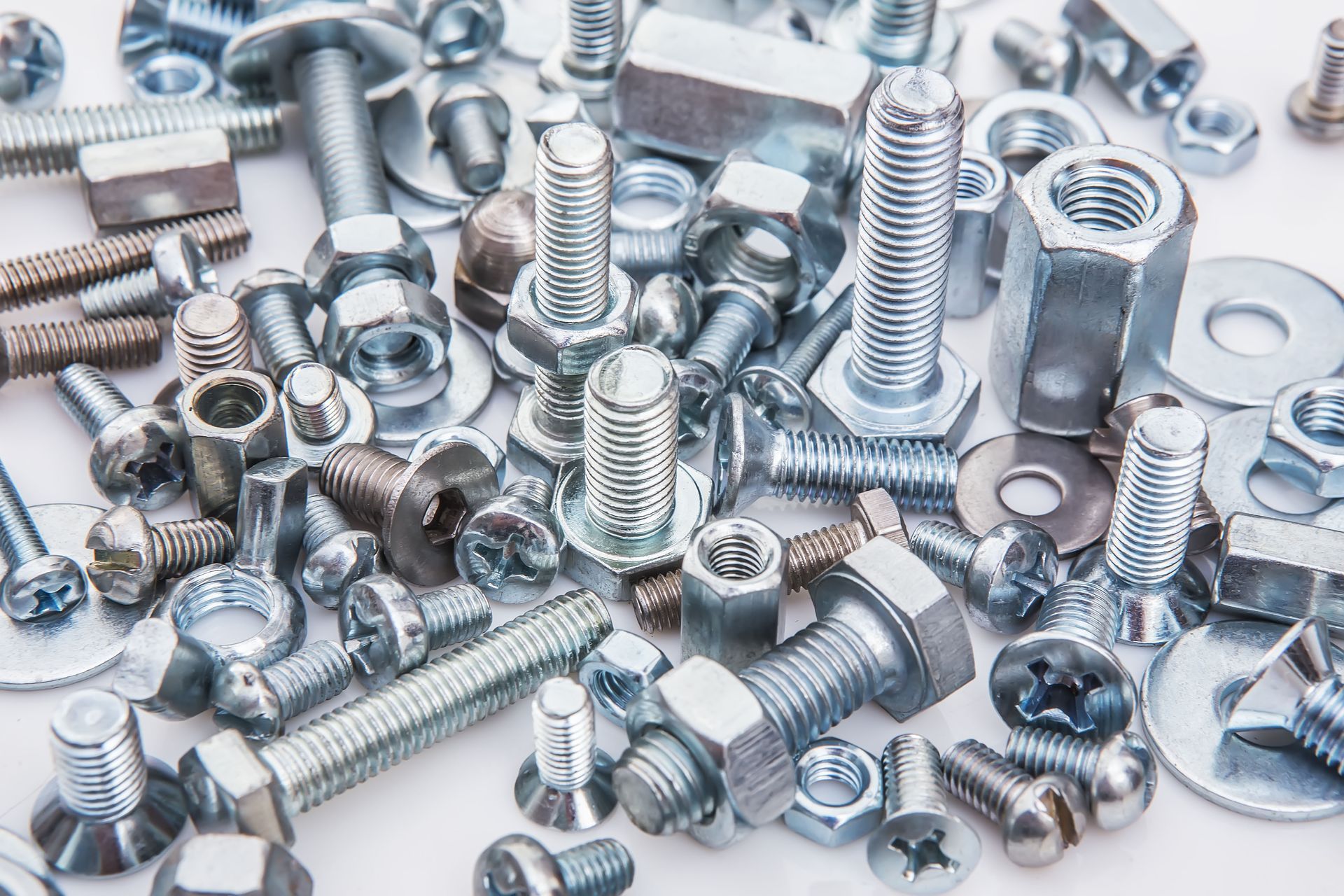

There’s a huge variety of industrial fasteners, and each type is built for a specific job. Screws are threaded and perfect for wood and metal where grip is essential. Bolts, combined with nuts, are used where strength and clamping force matter most. Nails are quick to install and common in woodworking. Rivets are permanent and great for high-vibration applications like aircraft. Then you have anchors, which secure objects into concrete or brick.

But the list doesn’t stop there — washers, clips, pins, and specialty fasteners all have unique roles, from distributing load to preventing parts from shifting. Some fasteners are designed for repeated assembly and disassembly, while others are meant to stay put for decades. Choosing the right one requires thinking about materials, load requirements, and environmental conditions like heat, moisture, or chemicals. Knowing the differences between these types isn’t just for engineers — it’s helpful for anyone who wants a solid, safe build. Using the wrong fastener can lead to loose joints, stripped threads, or even structural failure. Once you familiarize yourself with the main categories, you can choose confidently based on your project’s demands. Think of it as matching the right tool to the right job — except here, the fastener is the tool that keeps everything else in place.

Materials and Strength

The material of a fastener can completely change its performance. Steel is strong, affordable, and used in most general applications, while stainless steel adds corrosion resistance, perfect for outdoor or marine environments. Brass is soft but naturally resistant to rust, making it a good choice for decorative or electrical work. Aluminum is lightweight and often used in aerospace or situations where weight savings matter.

Each material has trade-offs, and selecting the right one can save you from costly replacements later. For instance, putting a plain steel fastener outdoors might lead to rust and failure, whereas stainless steel will last for years. Likewise, using a brass screw where high strength is needed can result in shearing or stripping. Material choice is a simple but critical step that ensures your project stays safe, functional, and long-lasting.

Sizing and Standards

Size absolutely matters with industrial fasteners. Every fastener has dimensions — diameter, length, thread pitch — that must match the job requirements. Using one that’s too small can cause it to snap under load, while one that’s too large might damage the material or not fit at all.

Thread standards also matter. A mismatch between a bolt and nut can result in stripped threads or a connection that feels tight but fails under stress. Following sizing and thread standards ensures components go together correctly and perform as intended. It’s a step that may seem small but has a big impact on safety, especially in industries like automotive or construction, where a single loose connection can have serious consequences.

Screws and Their Uses

Screws are probably the most familiar type of fastener and come in endless variations. Wood screws are designed to cut into wood fibers and hold pieces firmly together. Machine screws, on the other hand, are used with nuts or pre-threaded holes, making them perfect for metalwork. Sheet metal screws can pierce thin metal or plastic, holding panels and enclosures securely. Each one has a distinct job, which is why selecting the right screw type makes a huge difference in performance.

The versatility of screws is why they’re everywhere — in furniture, electronics, vehicles, and even toys. They’re easy to install with basic hand tools and just as easy to remove, making them perfect for projects that may require disassembly later. When choosing screws, consider their material, coating, and head style to match the project’s needs. This attention to detail helps prevent stripping, corrosion, or early failure.

Bolts and Heavy-Duty Connections

When strength is non-negotiable, bolts are the go-to choice. Unlike screws, bolts rely on nuts to clamp components together, which allows them to handle very high loads. Hex bolts are the most common and easy to tighten with wrenches. Carriage bolts have smooth, rounded heads that create a clean finish, often used in woodworking or furniture. Eye bolts are designed for lifting applications, giving you a secure point to attach cables or ropes.

Bolts are common in heavy-duty projects like bridges, building frames, and industrial machinery. Using the correct bolt grade (like Grade 5 or Grade 8) ensures it can handle the forces involved. Pairing bolts with washers helps spread out the load and prevent the surface from being damaged. If you’re working on anything that needs to stay together under stress, using the correct bolt setup is crucial for safety and performance.

Preventing Problems

Even the best industrial fasteners can fail if not used correctly. Common causes of failure include over-tightening (which can stretch or snap the fastener), under-tightening (leading to loosening), corrosion, and fatigue from vibration. Each of these issues can be avoided with proper selection, installation, and maintenance.

Preventive measures include applying the correct torque, using thread-locking compounds, and inspecting fasteners regularly for wear or damage. In industrial settings, scheduled maintenance is essential to catch potential problems before they cause downtime or safety hazards. Think of it as taking your car in for regular oil changes — small steps that prevent big failures later.

Fasteners might be small, but they literally hold our world together. Choosing the right type, material, and size isn’t just a technical detail — it’s the key to making sure your projects are strong, safe, and built to last. Taking the time to select high-quality industrial fasteners can save you from costly repairs, downtime, or even safety issues down the road. Need help finding the perfect fasteners for your next project? Contact Fasteners Inc today!

Share On: