How to Choose the Right Industrial Fastener for Your Next Project

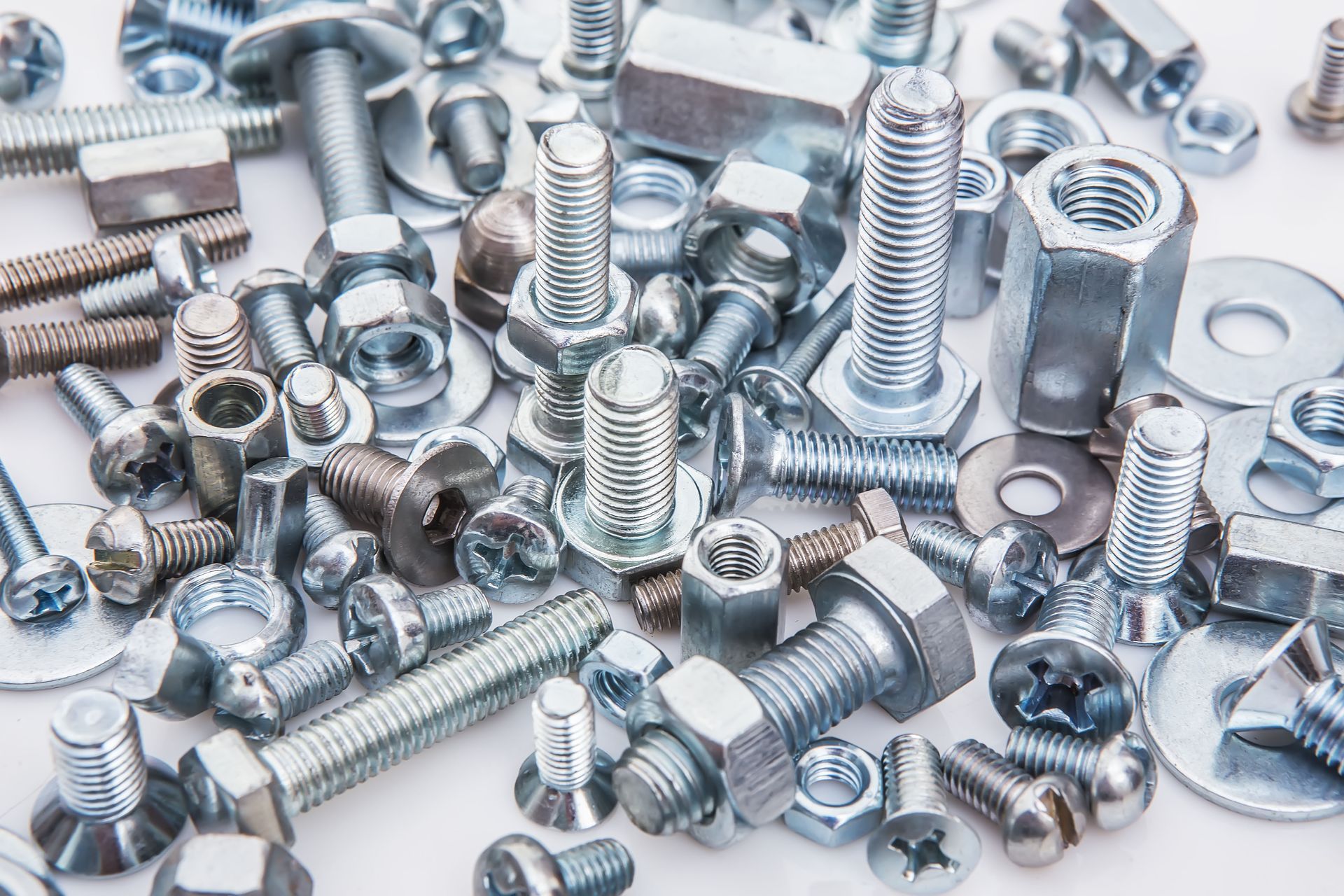

Understanding the significance of choosing the right industrial fastener is crucial for the success and longevity of any construction or manufacturing project. Are you looking for an in-depth guide on selecting the appropriate fastener tailored to specific project needs? By comprehensively examining types, materials, and standards, one can make informed decisions to enhance project outcomes. Industrial fasteners play a pivotal role in maintaining the structural integrity and functionality of assembled components. With a myriad of options available, here are some key factors to help you make the right choice, which can significantly impact project efficiency and safety.

Bolt Types and Their Applications

Bolt types vary widely, each engineered for specific applications and environmental conditions. Hex bolts are amongst the most common, used in construction and repair due to their robustness and ease of installation. Carriage bolts provide a smooth, domed head that enhances safety and aesthetics in visible applications. Eye bolts feature a loop at one end and are commonly used for lifting heavy loads, thanks to their high tensile strength. According to Mordor Intelligence, the industrial fasteners market in North America was approximately $20 billion in 2024 and is expected to reach $25.08 billion by 2030.

Structural bolts are specifically engineered for use in high-stress environments, critical in the assembly of large steel structures. They often feature a large head, which distributes the load more evenly and reduces the risk of material fatigue. Similarly, flange bolts come with a built-in washer for increased strength and rigidity, making them ideal for framing and machinery. Bolt selection must consider load demands, environmental conditions, and material compatibility to ensure optimal performance. Usage scenarios often dictate the choice of bolt type, emphasizing the need for tailored fasteners in different projects.

The flexibility of bolt types allows for varying levels of customization and adaptation to project-specific requirements. Achieving a balance between accessibility, function, and durability is vital when selecting bolts. Innovations in bolt engineering, including self-locking bolts, have enhanced safety and reduced maintenance in critical applications. Understanding detailed specifications, such as length, diameter, and thread type, ensures compatibility with other project components. By matching bolt types to application demands, construction integrity and longevity can be optimized, ensuring quality outcomes.

Screw Varieties and Usage Scenarios

Screws are versatile fasteners, available in a variety of shapes and sizes tailored to different materials and applications. Wood screws, for example, taper along their length to secure boards and planks effectively. Self-drilling screws offer convenience by eliminating the need for a pilot hole, ideal for quick assembly tasks. Machine screws come with fine threads, suitable for metal structures and components requiring precision. Each screw type caters to specific needs and materials, enhancing project adaptability and efficiency.

Threaded features determine the suitability of screws in various scenarios. Coarse threads provide better grip and resistance in soft materials, while fine threads are ideal for hard substrates and provide stronger locking. Captive screws are designed to remain attached to panels or doors in electronic enclosures, safeguarding against loss. In applications where aesthetics are paramount, countersunk screws offer a flush finish with surfaces, enhancing visual appeal. The choice of screw impacts not only the functionality but also the appearance and ease of maintenance of assembled products.

The range and diversity of screws extend their applications across multiple industries, from electronics to construction. Adapting screws to environmental challenges, such as moisture or chemical exposure, involves choosing suitable materials like stainless steel or coated variants. Understanding distinctions among head styles—such as Phillips, flathead, and torx—guides tool selection and installation. Proper screw selection balances form, function, and durability, aligning with project priorities and specifications. As industrial demands evolve, screw innovations continue to advance, offering enhanced utility and performance.

Rivet Options for Permanent Installations

Rivets are permanent fasteners, pivotal for applications requiring enduring load-bearing capacity and reliability. Solid rivets are one of the most traditional forms, used extensively in aircraft and structural framing for their strength and integrity. Blind rivets allow installation from one side, making them indispensable in scenarios with limited access, like panels and enclosures. Drive rivets offer ease of installation through a hammer strike, suitable for lightweight assemblies. Selecting the appropriate rivet is essential for balancing ease of installation with structural demands.

Material choice in rivets impacts not only the assembly strength but also its ability to withstand environmental challenges. Aluminum rivets are favored for their lightweight properties in applications where reduced mass is crucial, such as aerospace. Stainless steel rivets offer superior corrosion resistance, ideal for marine and outdoor environments. Copper rivets provide excellent electrical conductivity and are used in electronics and decorative applications. By matching materials and design to specific project needs, rivet installations can achieve sustainable and durable joinery.

Installation methods and tool requirements vary with rivet types, influencing project timelines and labor costs. Hydraulic and pneumatic riveting tools enhance efficiency and are often employed in high-volume industrial settings. Rivet choice should also consider expansion rates between joined materials to avoid stress-related failures over time. As innovations emerge, such as self-piercing rivets, the possibilities for rivet applications continue to grow, meeting complex industrial needs. Through careful consideration of these factors, rivets can provide secure and lasting solutions in industrial assemblies.

Anchors and Their Specific Uses

Anchors provide reliable support in substrate materials, enabling the secure installation of heavy loads or components. Expansion anchors, for instance, are commonly used in concrete to provide strong, secure holds under load. Sleeve anchors are versatile, offering a simple installation process suitable for masonry and concrete applications. Each anchor type addresses project-specific requirements, from load capacity to substrate compatibility.

Choosing an anchor demands an understanding of the base material and its inherent properties to ensure appropriate fastener performance. For projects in solid masonry, masonry anchors offer the best compatibility, providing a secure hold that benefits structural integrity. Hollow wall anchors are ideal for drywall partitions, providing a cost-effective and efficient means of securing fixtures. Considerations such as environmental exposure and aesthetic finish also guide the appropriate selection of anchors. Proper installation techniques, when paired with the right anchor, ensure safety and longevity.

Understanding the technical specifications and load ratings of anchors is crucial when selecting the appropriate type for your project. Analyzing tensile and shear strengths tailored to individual project needs enhances stability and security in installations. Technical data sheets often provide valuable insights into performance characteristics and installation guides, ensuring compliance with best practice standards. As new technologies emerge, like hybrid anchor systems, the adaptability and range of applications for anchors continue to evolve. By aligning anchor selection with precise engineering requirements, performance and resilience in structural joinery can be achieved.

Choosing the right industrial fastener is more than a routine step in construction or manufacturing—it's a critical decision that directly influences long-term project durability, safety, and performance. When the factors above are evaluated carefully, projects benefit from stronger connections, reduced maintenance needs, and improved structural integrity. With the industrial fasteners market continuing to expand and innovate, professionals who make informed choices can leverage these advancements to enhance efficiency and reliability. Ultimately, selecting the right fastener is an investment in the overall quality of your project. By applying the principles and insights mentioned above, you can approach your next build with confidence, knowing your fastening strategy supports both immediate performance and long-term success. Contact Fasteners Inc today to get started with top-of-the-line fasteners.

Share On: